Blacksmiths in Shefford

The village blacksmith would once have been a well-known feature of any rural community. In spite of the many blacksmiths that there must have been through the centuries it is quite rare to have much in the archives about them or the work that they did. For this reason we were very pleased to be offered some images and information about the blacksmith’s forge run by the Bird family, which stood in South Bridge Street throughout the 20th century (Z1748).

Bryant Bird shoeing horse, 1980 [ref: Z1748/5]

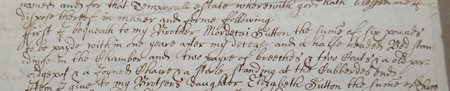

From the early 1600s to the 1730s the predominant family of blacksmiths in Shefford appear to have been named Sutton. In 1610 the parish register records the baptism of Agnes daughter of Nathaniel Sutton of Shefford, Blacksmith. Two more children of Nathaniel also appear in the register, Mordicaie (1613) and Joan (1615). However it seems likely that Nathaniel also had an older son called Thomas. Thomas Sutton, blacksmith of Shefford, first appears in a deed of 1650 and then appears in other documents in the 1660s and 1670s before dying in 1675. In his will, [ref: ABP/W1675-6/9], Thomas bequeaths various money and possessions to his wife Mary, to his brother Mordicaie, and to his nephews and nieces. The document is quite informative about where certain pieces of furniture are to be found in his house and it is nice to see that he leaves his brother, among other things, two pairs of breeches and two coats.

Extract from will of Thomas Sutton, 1675 [ref: ABP/W1675-6/9]

Although no mention is made of his blacksmith’s tools Thomas’s nephew, also called Thomas, is made executor and receives the residue of the estate, which probably included these. Mordicaie and Thomas junr also appear to have been blacksmiths. In the next generation the parish records show that William Sutton, blacksmith, married Mary Emery in 1713, Edmund Sutton, blacksmith is interred in 1721 and finally John Sutton, blacksmith, is interred in 1735.

Other mentions of blacksmiths can be found among the records: Francis Archer in 1614, Edmond Hogge in 1655, Jonathan Chambers who died in 1693 [ref: ABP/W1692-3/151] and left a close of pasture called the meeting house close ‘to the poore people called quakers’, John Piner (1702, 1705). After the Suttons came two other families of blacksmiths – the Whitbreads and the Gilberts.

In the 1740s Stephen Whitbread, blacksmith, and his wife Elizabeth have five children baptised. One of these, also called Stephen, also becomes a blacksmith in Shefford and he and his wife Fanny have three children baptised in the 1780s. We will return to the Whitbread family later.

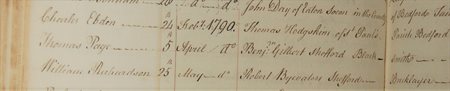

Also in the 1780s baptisms we find five children of Benjamin Gilbert, blacksmith, and his wife Rebecca. In 1789 the Bedford charity apprenticed a young lad, Thomas Page, to Benjamin Gilbert of Shefford, blacksmith (X109/1).

Extract from apprenticeship records of Bedford Charity [X109/1 page 55]

Between 1808 and 1837 documents refer to Benjamin Gilbert, his eldest son Benjamin, and Thomas a younger brother of Benjamin, all of whom were blacksmiths.

The first mention we have of where any of the blacksmith’s of Shefford may have worked is in 1834 when a document refers to a piece of land in Water End Shefford ‘whereon the cage and a blacksmith’s shop heretofore stood’ [ref: X465/320].

In 1841 Stephen Whitbread aged 29 is a smith living in Shefford; in later census he is described as a whitesmith. George Whitbread, aged 25 is a blacksmith in Campton, and in Clifton we find George’s father John Whitbread, aged 45, who is also a blacksmith. By 1861 George is a blacksmith but his wife, Mary, is a publican and they are living at the Green Man pub in Shefford (later known as the Brewery Tap). George and Mary’s eldest son, William, doesn’t live with his parents and siblings on either the 1851 or 1861 census but is instead living with his grandparents, John and Mary Anne, in Clifton. The house is also occupied by John’s nephews George and John who are also described as blacksmiths.

It is young William that is of particular interest. In 1870 William marries Sarah Ann and from the 1871 census we know that William was by then working as a blacksmith in Shefford. Ten years later he is described as a blacksmith employing 3 men. By 1901 William has branched out and he and his son Ralph are described as blacksmith and cyclemaker. By 1911 William, now 61 years old, is just a blacksmith and Ralph is described as an ironmonger. At some point William Whitbread moved the business from Northbridge Street to Southbridge Street. The smithy appears on the first edition Ordnance Survey 25 inches to the mile map of 1883 (Central Shefford), marked on in plot 67 just behind St Michael’s Church, and off Southbridge Street.

At this point 28 year-old John Bird arrives from Lutton Northamptonshire and in March 1912 advertises that he has purchased W Whitbread’s ‘old established Business and hopes by strict attention to business to merit a continuance of the support so liberally extended for over a century’ [ref: Z1748/1]. John paid William Whitbread, whose family ran the blacksmith business beforehand, in gold sovereigns (as mentioned in a local Bedfordshire newspaper in 1962 as part of an article celebrating 40 years of John Bird being a blacksmith in Shefford).

John Bird and daughter Maggie outside the forge, 1927 [ref: Z1748/2]

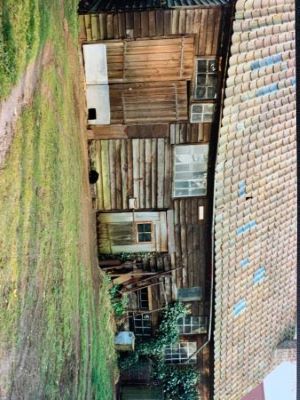

In 1933 John’s 14 year-old son Bryant started working alongside his dad, until he left for the war. After returning from the war, Bryant returned to work in the forge and took over from his father in the early 1950s, although John would still pop in from time to time. In 1957, Bryant purchased the forge from C.E. Tingey and continued working there until 2000.

Bryant’s daughter remembers ‘No job was too big or too small for John and Bryant. From sharpening garden shears and shoeing horses, to making implements and repairing large machinery. Bryant would even design and make ornate wrought-iron gates, and one of his proudest moments was creating a large mincing machine for the West End musical Les Mis (in the early 1990s). In the yard in front of the forge was a wheelwright’s platform, which is where wooden wheels would receive their final metal rim. The blacksmith’s job was to construct a metal outer-rim to fit snugly on the wooden wheel, which was only possible by heating the metal to a very high temperature. Bryant also used high temperatures in a technique called ‘hot shoeing’. This is when the metal of a horseshoe is heated to a red hot heat so that the material is more malleable. Many people would prefer this process as it was said to provide a better fit. Hot shoeing would fill the forge with a cloud of very pungent smoke, and his family could always tell when he’d been hot shoeing, as they could smell it on his clothes the instant he came home! During the early 1950s, John and Bryant would often take part in farrier competitions and put on horseshoeing displays at various agricultural shows, and would often return with prizes. In the late 1950s/early 1960s, Bryant would travel to shoe local horses. With no driving license or car, Bryant would strap all his tools onto the back of his bicycle, and sometimes his daughter would travel with him, sitting on a little seat at the front of the bike fixed to the crossbar. It took about an hour for Bryant to remove the shoes, trim the hooves, and give the horse a new set of shoes. In the mornings he’d tend to be in the forge, then would travel to different locations in the afternoon, always making sure the job was done well. In the mid-1960s Bryant learnt to drive and bought a van which enabled him to travel further and quicker (which also gave his daughter a more comfortable journey!) Bryant always had time for everyone, and would often have groups of school children around the anvil explaining how things were done, which is an experience that has stayed in the memories of many Shefford inhabitants.’

Bryant continued working in the forge until 2000, when he sold it. The forge was demolished in the mid to late 2000s after providing the community of Shefford with 200 years of service.

Blacksmith’s forge at South Bridge Street, Shefford before demolition, 1990 [ref: Z1748/6]