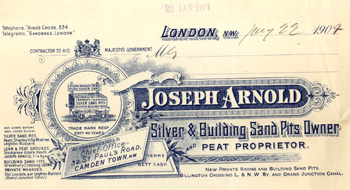

Joseph Arnold letter head

Bedfordshire and Luton Archives and Records Service has material on two of Heath and Reach and Leighton Buzzard's former principal sand quarrying firms - J.Arnold & Sons Limited and George Garside (Sand) Limited. J.Arnold & Sons was actually established by John Arnold (1816-1880) who began to quarry sand in Heath & Reach around 1860. Bedfordshire & Luton Archives & Records Service has a company history written by P.R.Arnold in 1986 as well as a number of facsimile articles in trade magazines [CRT160/164].

John Arnold had three sons, Joseph (born about 1841), John Alfred (born about 1848) and George, born about 1855). Although John Alfred became a Baptist missionary the three brothers were partners following the death of their father in 1880, as J.J.& G.Arnold's Silver Sand.

The Arnold brothers opened a quarry in Flitwick about 1902 but sold it in 1922. In 1918 the company name changed to Joseph Arnold & Sons. Joseph had died in 1911 and left the firm to his two sons Albert and Ernest. The company became a limited company in 1937. In an article in Cement, Lime & Gravel magzine in May 1934 it was stated that the firm produced over forty different grades of sand and a few of the main purposes were outlined: foundry sands; building sand for mixing with cement; glass manufacture; water filtration at water and sewage plants; horticulture; sand blasting. Some of the ironstone extracted during the quarrying process was also used for building houses and rockeries; shingle extracted was used in road work.

The company had the following quarries:

- Chamberlain's Barns Quarry on Heath Road, Leighton Buzzard;

- Chance's Quarry in Heath and Reach;

- Double Arches on Eastern Way, Heath and Reach (opened in 1916 and closed in 1985);

- New Trees Quarry at Shenley Hill, Heath and Reach (opened in 1964);

- Nine Acres Quarry at Mile Tree Road, Heath and Reach;

- Pratt's Quarry on Billington Road in Leighton Buzzard;

- Stone Lane Hill Quarry on Woburn Road, Heath and Reach

- Twenty One Acres Quarry at Mile Tree Road, Heath and Reach.

In addition the firm, with Garside's, used the Leighton Buzzard Light Railway from its opening in 1919 until it closed as a working railway in 1982. The railway conveyed the sand to Billington Road where most of it was washed (some quarries had small washing plants on site). From 1986 the washing took place at the closed Double Arches pit. Main line railway sidings were also located at Billington Road connected, via the Leighton Buzzard to Dunstable railway, with the main line from London to Glasgow.

An article on J.Arnold & Sons appeared in the May 1936 edition of Cement, Lime & Gravel. The article described the sand washing plant at Billington Road, Leighton Buzzard in some detail as well as the various pits. Of operations in general, it said: "It is worthy of note that, throughout the quarries the locos and wagons have been, as nearly as possible, standardised. The locos employed are all Simplex petrol machines, and the wagons are 1 yard Hudson tipping wagons, with special large wheels and axle boxes. By experience the ordinary small wheels and roller bearings were found to be too troublesome for the long runs they were called upon to do. A few large eight-wheel bogey wagons are employed, chiefly for bagged materials".

"The washing plant is standard at all quarries where sand is washed and consists of the improved type of washer to the Firm's design. It is driven by Ruston crude oil engines and with the exception of the one gas engine at Billington Road, all power units are Ruston crude oil engines which have proved exceptionally economical.

"At the drying plant the sand is run up a slight slope and tipped near the drying floors. These floors run the whole length of the building and are heated by four coke furnaces. The sand is spread evenly over the floors and constantly turned. When dry it is shovelled into the various feed hoppers of a battery of mechanical screens".

"Below each screen are the bagging hoppers, from which the screened products are dropped direct into bags. A light railway siding runs along the bottom side of the plant and here the bagged material is loaded into trains which deliver it at Billington Road, where it is transhipped to main line wagons for despatch. The shingles, derived from the various sands treated here and at the washing plants, are used for road work and other purposes".

"Such sand as is sent away by road is loaded into lorries by means of a gantry from which wagons are tipped direct into the lorries or to reserve hoppers. This type of gantry is standard throughout the quarries and is usually built on sand lime brick pillars. Most of the engine houses are also built of the sand lime brick and make a very clean looking building. One building, however, is almost entirely made of limestone derived from the Twenty One Acre pit. It was erected in 1918 and shows no signs of weathering".

J.Arnold & Sons Limited was dissolved in June 1989. Many of their pits were subsequently worked by WBB Minerals Limited.